1. On the premise of ensuring the hardness of the mold, try to use pre-cooling, graded cooling quenching or warm quenching process.

2. Changping heat treatment is recommended. For sophisticated and complex molds, if conditions permit, the nitriding heat treatment plant recommends vacuum heating and quenching and cryogenic treatment after quenching as much as possible.

3. For some sophisticated and complex molds, pre-heat treatment, aging heat treatment, and quenching and tempering nitriding heat treatment can be used to control the accuracy of the mold.

4. When the nitriding heat treatment plant repairs defects such as mold blisters, pores, and wear, it uses cold welding machines and other repair equipment with little thermal influence to avoid deformation during the repair process.

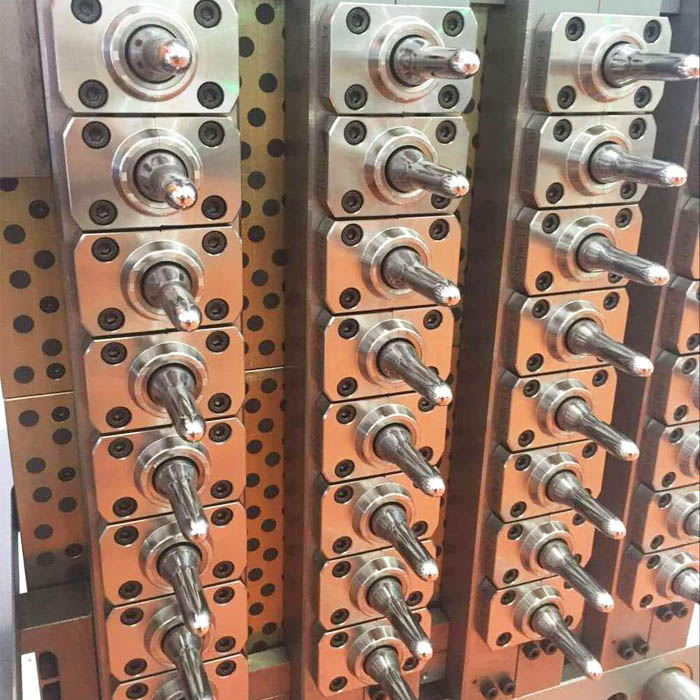

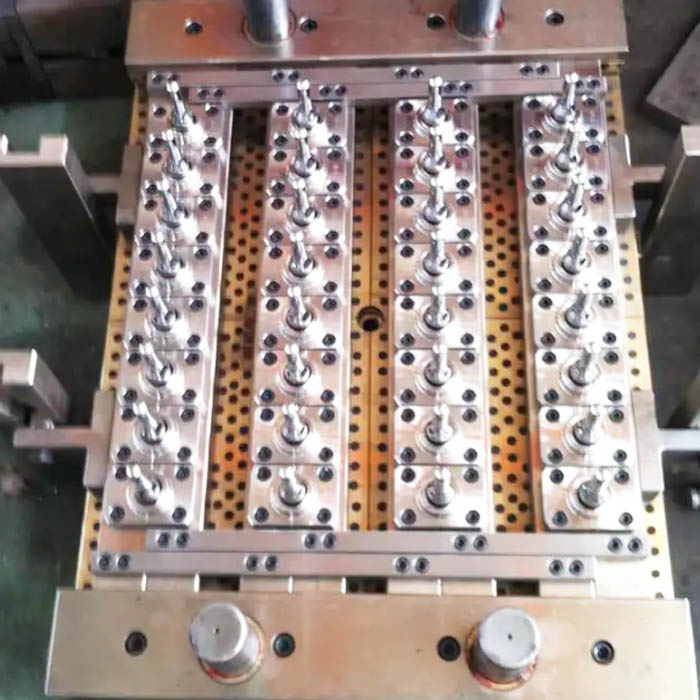

5. The mold structure design should be reasonable, the thickness should not be too disparate, and the shape should be symmetrical. Experts said that for large deformation molds, the deformation law should be mastered, and machining allowance should be reserved. For large, sophisticated and complex molds, a combined structure can be used.

6. Precise and complex molds should be pre-soft nitrided to eliminate residual stress generated during machining.